Jute Fibres – The Fibre Of Future

Did you know? Jute is popularly called Golden Fibre due to its colour and high cash value. Jute fibres are the second most important vegetable fibre after cotton. It is a common textile manufactured worldwide to make clothes for wrapping bales, making sacks, and coarse clothes. Raw jute plays an important role in India’s economy. Majorly used in packaging industries, jute has now emerged as a versatile raw material for diverse applications such as the paper industry, building, and automobile industry, use as a soil saver and decorative, and furnishing materials. Apart from that, jute fibres have some more features that make them more versatile, such as:

Also check out-Difference between wood of Gymnosperms and Dicots (Soft Wood vs Hard Wood) – My Biology Dictionary

- Easy availability

- Inexhaustible quantity at a comparatively cheaper rate

- Can be easily blended with other natural and man-made fibre

- Environment-friendly

Table of Contents

The Biology of Jute Fibre

Botanical name: Corchorus species

Origin of word Corchorus: Greek literature- ‘korkhoros’ meaning ‘pot herb’

C. olitorius (tossa jute)

C. capsularis (white jute)

Family: Malvaceae (Earlier placed in Tiliaceae)

Subfamily: Grewioideae

Chromosome Number: 2n = 14

It contains 53 – 63% cellulose (in cotton more than 90%); hemicellulose 22 – 26%; lignin 11-12% and other

components such as waxes, gums, fats, and minerals. High content of lignin (in comparison to cotton) reduces its durability.

Origin And History of Jute Fibers

The primary centre of origin of C.olitorius in Africa with the secondary centre in the Indo-Burma of India. While C.capsularis is believed to have originated from Indo-Burma. Jute fibres were used as food in Ancient Egypt. During the eighteenth and nineteenth centuries, the jute industry boomed but then faced a fall around the 1970s due to the emergence of synthetic fibres. Presently jute has started gaining importance in the 21st century due to its availability and biodegradable nature

Image source: https://larrylouie.com/indian-jute-mill

Production of Jute Fibres

India dominated jute production and produced 99 per cent of the world’s production before 1947. After the partition, most of the superior jute cultivation land area went to Pakistan whereas India retained the jute mills. India’s jute production is presently led by West Bengal. India is the world’s largest jute producer but imports a very less quantity of raw material (approximately 18000 tonnes) as compared to other countries like the US, China, Japan, the UK, France, Germany, etc.

Image source: https://www.picfair.com/pics/04904046-jute-processing-work

Morphology of Jute Plants

Jute plants of both the mentioned species are woody, tall plats ranging 3-4 m, usually unbranched with few branches on top. Leaves are simple and borne alternatively. they have yellow-coloured flowers and fruits are capsules with many seeds.

Corchorus capsularis (White Jute)

White jute fibres are the most adaptable variety of jute that is being grown since ancient times. Historically, it was used for ropes twines, and other household purposes. It is believed that ancient Indians wore dresses of white jute. Jute is grown in 75% of the total cultivated area in India, but the quality of whitish fibre is inferior. It has a bitter taste due to the presence of ‘corchorin’, a bitter glycoside. This is the reason why it is also known as tita or bitter pat. It is a lowland species.

Corchorus olitorious (Tossa Jute)

Tossa jute fibres are much better quality fibres. They are silkier, softer, and stronger than white jute fibres. This variety shows good sustainability in the Ganga Delta region. These species are locally known as mitha or sweet pat as they do not have a bitter taste (due to the absence of corchorin). Flowers are yellowish in colour, relatively larger in size in comparison to C. capsularis, and at maturity develop into long, cylindrical, ridged capsules with characteristic beaks.

Image source: https://www.dreamstime.com/photos-images/tossa-jute.html

Cultivation of Jute Fibres

Jute is primarily a monsoon crop and grows best in warm and wet conditions. Thus, alluvial soil with standing water is ideal for jute production. A temperature ranging from 20-40 degrees celsius and relative humidity of 70-80% is required for the successful cultivation of jute fibre. Jute thrives best where annual rainfall ranges from 150-250 cm, especially during sowing time. It does not require many fertilizers and pesticides like cotton.

Harvesting of Jute Fibres

Jute fibres are blast fibres that can be harvested after a period of vegetative growth which is around 4-6 months.

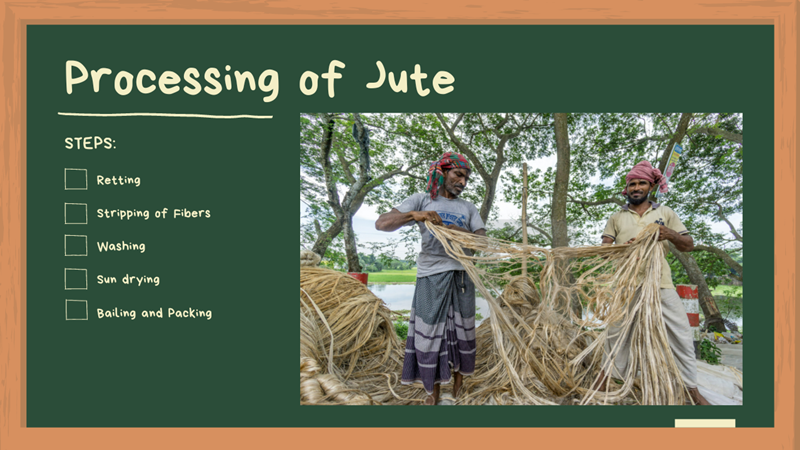

PROCESSING OF JUTE FIBRES

Retting

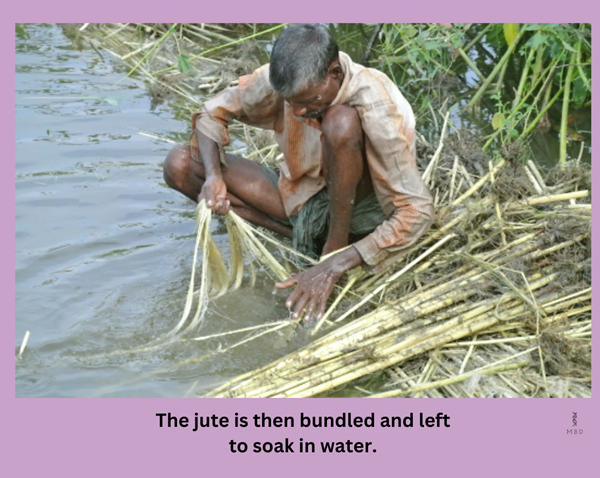

Retting is a microbiological process that governs the quality of the fiber and thus it is an important operation. In the process of getting, the outer bark loosens as well as the fibers from the woody central stalk get separated. The woody bundles are placed layer by layer at right angles on top of each other and kept in 30cm deep water. Then they are covered with water hyacinth or any other weed that does not release tannin and iron.

Retting is best done in large volumes of slow-moving, clean water. This takes about 10-30 days. The optimum temperature for retting is 34 degrees Celcius. If the fibers come out easily from the wood just by pressing with the thumb, retting is considered complete.

Stripping or Extraction of Fibre

It is the process of removing the fibres from the central woody stick. There are two methods for the extraction of jute fibres. The single plant extraction method and the Beat-Brek-Jerk method.

Image Source: www.jute.com

SINGLE PLANT EXTRACTION METHOD:

In this method, four to five reeds are taken and stripped out from the bottom to the top. The fibre is slipped off up to about 8 to 10 cm and pulled slowly from the rest of the stick.

BEAT-BREAK-JERK EXTRACTION METHOD:

In this method, a handful of bundles are taken and beaten at the base with a mallet. Then the woody core is broken, twisted, and shaken vigorously to and fro in the water. The broken sticks slip out and water is wrung out of the fibre.

Image Source: www.ludlowjute.com

For the extraction of fibres, the single fibre extraction method is better and highly recommended as it gives better quality jute fibres. On the other hand, the beat-break-jerk method affects the quality of the fibre and makes it entangled.

Washing

This is the process of cleaning the stripped jute fibres in clean water to remove the adhering periderm and pith. The extracted jute fibers can be dipped in tamarind water for 15 minutes to remove the black colour. then it is again washed with water.

Sun Drying

After washing, water is squeezed out from the fibres. Then it is spread on the bamboo railing for sun drying for about two to three days. This not only dries the fibres but also makes them more tensile.

Bailing And Packing

Once the fibres get dried, they are rolled into bundles and pressed into bales depending on their quality and grade. After bailing raw jute is ready to be transported to jute mills or the jute market.

Jute is being widely used in various industries for packaging and other good servicing tasks due to its high efficiency as compared to plastics. It is thus considered the fibre of the future not only due to its low cost and strength among all natural fibres but also because of its biodegradable and eco-friendly nature.

Thank you for reading!

Team MBD

Watch processing of Jute- (1) Processing cycle of Jute – YouTube

Nice content 😃👍