Types of Bioreactors

Biotechnology is the science of manipulating biological systems to manufacture new products and investigate how organisms work. Scientists use the genetic material of organisms to make products such as foods, fuels, and pharmaceuticals. It is the future of medicine, and it can be used to treat and cure a wide variety of diseases and conditions. Hence, it becomes necessary to make the desirable products available to as many people as possible. This is where bioreactors come in. Let us have a look at the role of bioreactors in obtaining a gene product as well as the different types of bioreactors.

Also check out- Salient features of a cloning vector – My Biology Dictionary

Table of Contents

Desirable Gene Product

A gene product is a complex biomolecule produced by an organism’s genes. Biotechnology is often used to alter the genetic makeup of a being in order to obtain desirable gene products. Gene products are usually proteins or other biomolecules, such as carbohydrates and lipids

The ability to alter the characteristics of a living being through the use of biotechnology is a rapidly developing field of science.

One of the most common ways to alter the characteristics of a living being is to alter the genetic makeup of the being. Recombinant DNA technology allows scientists to take genes, either from one species or from several species, and combine them to make new, artificial genes that produce new, artificial proteins. This enables the production of desirable gene products that can be purified and processed on a large scale and made available to the masses.

Bioreactors

To begin with, bioreactors are vessels used to grow large batches of cells, cultures, or tissue in a controlled environment. Bioreactor cultures can be used to produce a variety of chemicals, including antibiotics, vaccines, enzymes, and fragrances. They are used in several industries, including food and beverage processing, pharmaceuticals, and biotechnology.

Most bioreactors are simple cylinders or spheres, but more elaborate designs are used to increase volume or to better control environmental conditions.

A typical bioreactor has a series of tubes running along the inside of the vessel that is essential in order to provide optimal conditions for the growth of the culture such as maintaining the temperature, nutrients, pH etc. It is filled with the culture medium, which contains the recombinant microorganisms. These microorganisms feed on the nutrients in the medium and produce the desired product, which is then separated and purified as a part of the down streaming process.

A bioreactor can process 100-1000L of culture

Bioreactors come in many different shapes and sizes and are used to grow a variety of biological materials and cells. Let us discuss a few of them.

Types of Bioreactors

There are many different types of bioreactors, from simple open systems to complex closed systems. Each type of bioreactor has unique characteristics that make them better suited for different applications and requirements. A few of them are:-

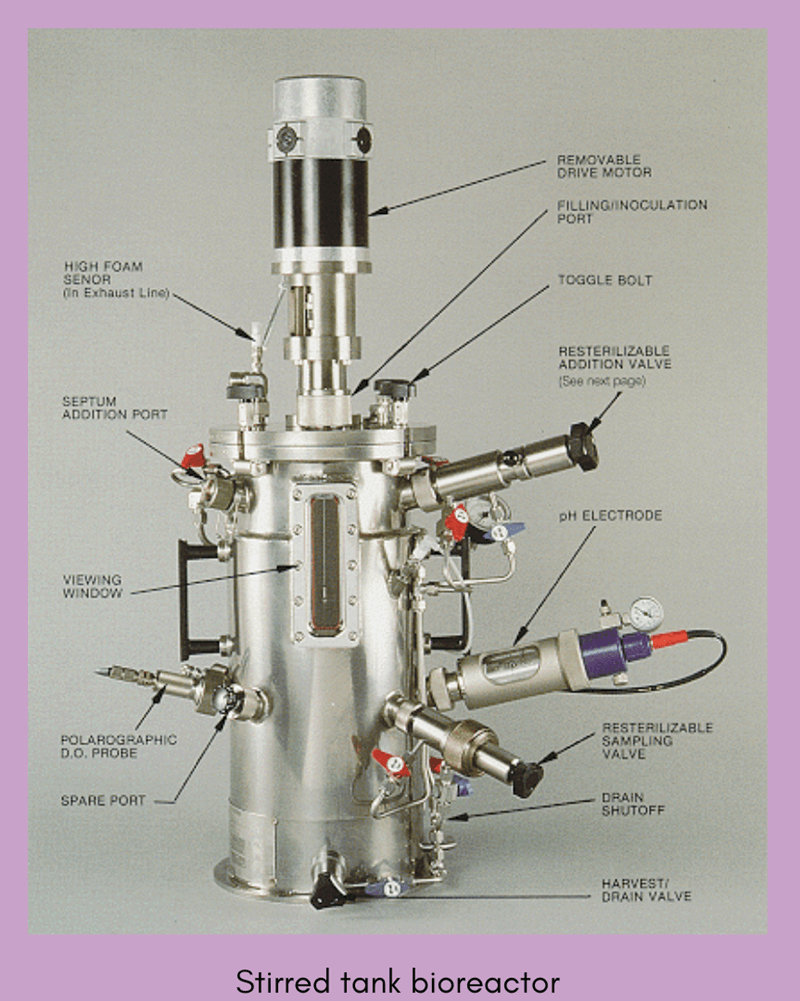

1. Stirred-tank Bioreactor

In a stirred tank bioreactor, the medium is continuously circulated throughout the reactor by an internal circulation system. The medium is usually pumped through the reactor and mixed by mechanical agitators and agitation devices, such as impellers. The stirring mechanism used to mix the medium is called a stirrer. It allows the even mixing of oxygen and nutrients throughout the vessel.

The stirred tank bioreactor is the most common type of bioreactor used by industry

Image source: http://www2.hawaii.edu/~wsu/bioreactor/sld004.htm

This type of bioreactor is often used when the flow of the medium is controlled and stable. For instance, in protein purification applications. Common uses for the stirred tank bioreactor include the following:

- the production of enzymes and proteins,

- the production of antibiotics,

- the production of biofuels, and

- the production of chemicals and materials.

The stirred tank bioreactor is a common bioreactor in industrial settings, as it is simple and efficient to operate, requiring minimal maintenance. It is also an excellent choice for scaling up a bioreactor, as it is easy to increase the scale of the reactor by adding more cylinders.

Image source: NCERT

2. Sparged Stirred-tank Bioreactor

A Sparged Stirred-Tank Bioreactor (SSTB) is a type of continuous culture bioreactor. The major difference between Sparged stirred tank and a simple stirred tank bioreactor is that the medium in Sparged stirred tank bioreactor is continuously supplied with sterile air during the fermentation process. This helps to increase the oxygen uptake of the culture by increasing the surface area for oxygen transfer.

Besides the oxygen delivery system, SSTB has other systems in place to control various conditions. These include pH, temperature, foam control, agitator system, samplings ports etc.

This increased oxygen uptake allows for cells to grow to a larger scale and to produce more biomass, which improves the reaction rates and productivity of bioreactors without the need for expensive and space-consuming pumps. The SSTB can be used for the growth of microbes, yeasts, and molds for the production of fermented foods and beverages.